Shopping Cart

There are no more items in your cart

Basic electrodes for structural steel AWS 7018

Elektrodai AWS E7024 Ø3.2x350 5kg

Basic electrodes for structural steel AWS 7018

Elektrodai Elga P48P 2.0x300mm 1.7kg

Basic electrodes for structural steel AWS 7018

Elektrodai ESAB OK 48.00 VacPac - 4.0mm x 350mm / 1.7kg

Basic electrodes for structural steel AWS 7018

Elektrodai ESAB OK 48.00 (Ø4.0mm X 450mm) 4.1kg

Basic electrodes for structural steel AWS 7018

Elektrodai ESAB OK 48.00 (Ø2.5mm X 350mm) 4,3kg

Basic electrodes for structural steel AWS 7018

Elektrodai ESAB OK 48.00 (Ø3.2mm X 450mm) 6kg

Basic electrodes for structural steel AWS 7018

Elektrodai ESAB OK 48.00 (Ø2.5mm X 350mm) 0.7kg VacPac

Basic electrodes for structural steel AWS 7018

Elektrodai ESAB OK 74.46 - 2.0mm x 300mm / 0.6kg

Basic electrodes for structural steel AWS 7018

Elektrodai Böhler Q E 7018 - 4.0mm x 450mm / 5.9kg

Basic electrodes for structural steel AWS 7018

Elektrodai ESAB OK 48.00 (Ø4.0mm X 450mm) 6.2kg

Basic electrodes for structural steel AWS 7018

Elektrodai Elga P48M 2.5x350mm 4.2kg

Basic electrodes for structural steel AWS 7018

Elektrodai Böhler Q E 7018 - 3.2mm x 350mm / 4.2kg

Basic electrodes for structural steel AWS 7018

Elektrodai AWS E7024 Ø5.0x350 5kg

Basic electrodes for structural steel AWS 7018

Elektrodai AWS E7018 Ø3.2x350 5kg

Basic electrodes for structural steel AWS 7018

Elektrodai ESAB OK 74.46 - 3.2mm x 450mm / 2.0kg

Customers who bought this product also bought:

Rutile electrodes for structural steel AWS 6013

Elektrodai AWS E6013 - 2.5mm / 2.5kg

Basic electrodes for structural steel AWS 7018

Elektrodai Elga P48P 2.0x300mm 1.7kg

Rutile electrodes for structural steel AWS 6013

Elektrodai ESAB OK 46.30 (Ø2,5mm X 350mm) 5,0kg

Structural steel welding wires

Suvirinimo viela ESAB OK Tigrod 12.64 2.0mm 5kg

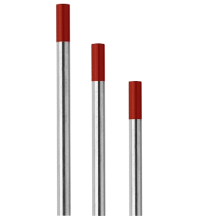

Tungsten electrodes

TIG volframo elektrodas WT20 175mm (1 vnt.) raudonas - 1.6 mm

Product added to compare.

Search

You need to login or create account

Save products on your wishlist to buy them later or share with your friends.

Product added to wishlist